Government Initiatives and Support

Government initiatives aimed at promoting digital transformation significantly influence the industrial IoT-platform market in China. The Chinese government has implemented various policies and funding programs to encourage the adoption of IoT technologies across industries. For instance, the 14th Five-Year Plan emphasizes the importance of integrating advanced technologies into manufacturing processes. This support is expected to drive investments in industrial iot-platforms, as companies seek to align with national objectives. As a result, the market is anticipated to witness substantial growth, with projections indicating an increase in market size to over $20 billion by 2030. Such initiatives not only enhance competitiveness but also foster innovation within the industrial sector.

Emphasis on Supply Chain Optimization

The industrial IoT-platform market in China is experiencing an increased emphasis on supply chain optimization. As businesses aim to enhance their operational resilience, the integration of IoT solutions into supply chain management is becoming increasingly prevalent. By utilizing real-time data and analytics, companies can improve inventory management, reduce lead times, and enhance overall supply chain visibility. This trend is particularly relevant in the context of global supply chain disruptions, where agility and responsiveness are paramount. The market for industrial iot-platforms that facilitate these optimizations is projected to grow, with estimates suggesting a potential market size increase of over $15 billion by 2030. Such advancements are likely to play a crucial role in ensuring the competitiveness of Chinese industries.

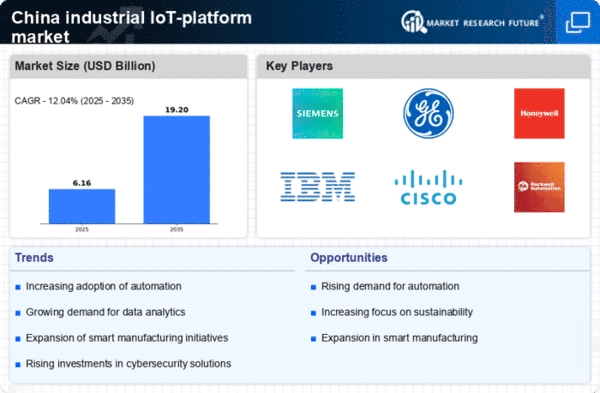

Rising Demand for Smart Manufacturing

The industrial IoT-platform market in China is experiencing a significant increase in demand for smart manufacturing solutions. This trend is driven by the need for enhanced operational efficiency and productivity across various sectors. As industries increasingly adopt automation technologies, the market is projected to grow at a CAGR of approximately 25% from 2025 to 2030. The integration of IoT platforms facilitates real-time monitoring and data analytics, enabling manufacturers to optimize processes and reduce downtime. Furthermore, the Chinese government's support for smart manufacturing initiatives, including the Made in China 2025 strategy, is likely to bolster the adoption of industrial iot-platforms, thereby transforming traditional manufacturing into a more agile and responsive ecosystem.

Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into the industrial iot-platform market is reshaping how data is utilized in manufacturing processes. Chinese companies are increasingly adopting AI-driven analytics to derive actionable insights from vast amounts of data generated by IoT devices. This trend is expected to enhance operational efficiency and decision-making capabilities. By 2030, it is estimated that AI and ML applications in the industrial sector could contribute to a potential increase in productivity by 20-25%. As organizations recognize the value of intelligent data processing, the demand for advanced industrial iot-platforms that incorporate these technologies is likely to rise, fostering innovation and competitiveness.

Growing Focus on Predictive Maintenance

In the context of the industrial iot-platform market, there is a growing emphasis on predictive maintenance strategies among Chinese manufacturers. By leveraging IoT technologies, companies can monitor equipment health in real-time, allowing for timely interventions before failures occur. This proactive approach is expected to reduce maintenance costs by up to 30% and improve overall equipment effectiveness. As industries strive to minimize downtime and enhance productivity, the adoption of predictive maintenance solutions is likely to accelerate. The market for industrial iot-platforms that support these capabilities is projected to expand significantly, reflecting a shift towards data-driven decision-making in maintenance practices.